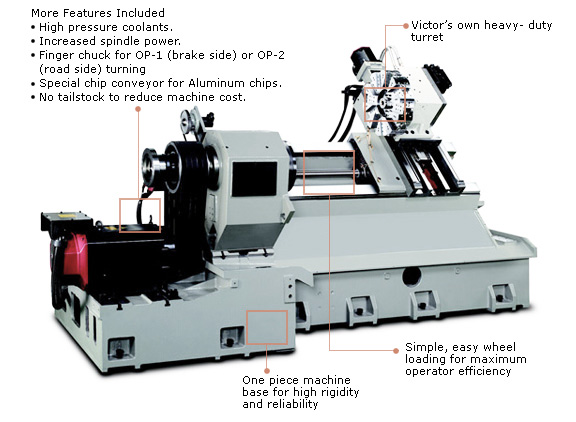

Horizontal Alloy Wheel CNC Lathe

Vturn-18W/22W

One piece slant bed lathe has been specifically developed for max. efficiency in Alloy wheel processing.

Horizontal type lathe minimizes chip build up in wheel to prevent swarf marring the surface during operation. The machine's ample capacity allows wheels of up to 18" to be processed as standard. Specific features have been added to improve machine efficiency, including strong coolant flow.

- Cost effictive solution for turning wheel size up to 22 inches.

- Fully enclosed guarding with high pressure coolant and large coolant tank minimizes the chip and coolant leakage.

‣ Meehanite cast iron structure with hardened box slideways quickly dampers cutting vibrations for high accuracy even under heavy cutting.

| ITEM / MODEL | Units | Vturn-18W | Vturn-22W |

|---|---|---|---|

| Swing over bed diameter | mm (inch) | 680 (26.7) | 790 (31.1) |

| Standard turning diameter | mm (inch) | 430 (16.9) | 600 (23.6) |

| Maximum turning diameter | mm (inch) | 530 (20.8) | 620 (24.4) |

| Swing over carriage | mm (inch) | 520 (20.4) | 620 (24.4) |

| Hydraulic 3 jaw finger chuck | OP1 or OP2 (12"~18") | 15"-20" or 17"-22" | |

| X axis travel | mm (inch) | 315 (12.4) | 350 (13.8) |

| Z axis travel | mm (inch) | 750 (29.5) | 750 (29.5) |

| Rapid feed - X/Z axis | m/min (ipm) | 20/20 (787/787) | 18/20 (709/787) |

| Feed motor - X/Z axis | kW (HP) | 3.0/4.0 (4/5.4) | 4.0/4.0 (5.4/5.4) |

| Max. Spindle speed | rpm | 2500 | 2000 |

| Spindle nose | A2-8 | A2-8 (A2-11 built-in) |

|

| Spindle bearing dia. | mm (inch) | 130 (5.1) | 160 (6.3) |

| Spindle taper | 1/20 | 1/20 | |

| AC Spindle motor (Cont. / 30 min.) | kW (HP) | 30/37 (40/50) | 30/37 (40/50) |

| Hole through spindle | mm (inch) | 86 (3.4) | 105 (4.13) |

| Hole through draw tube | mm (inch) | 75 (2.95) | 91 (3.58) |

| Tool stations | No. | 10 | 12 |

| I.D. tool size (max) | mm (inch) | 50 (2) | 50 (2) |

| Standard O.D. tool size | mm (inch) | □32 (1¼) | □32 (1¼) |

| Coolant capacity | liter (gallon) | 360 (94.7) | 400 (105) |

| CNC Controller | Fanuc | 0i-T (8.4") | 0i-T (8.4") |

| Approx. machine size (with chip conveyor) | m (inch) | 4.73 x 2 x 2.15 (186 x 79 x 85) | 5.1 x 2.5 x 2.4 (198 x 100 x 95) |

| Net weight | Kg (lbs) | 6500 (14430) | 9000 (19800) |